DOWNLOAD complete documentation, parts and distributers

DOWNLOAD schematic high voltage (EAGLE .sch)

DOWNLOAD schematic microcontroller (EAGLE .sch)

DOWNLOAD Software for microcontroller Atmel ATMega88

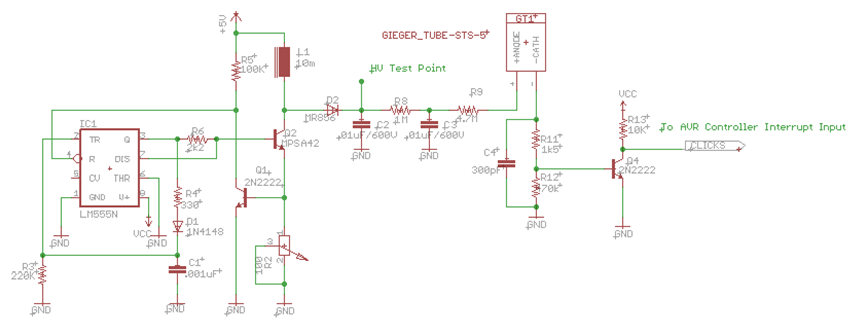

Schematics around counter tubes are mainly related to

the high voltage generation.

Examples are widely spread in the net. A special issue of this counter is beside the

generation of the high

voltage, the microcontroller computing the clicks and display

the data on an

LCD. Here the main features of this design:

- Software controlled speaker pulse width “click”

- Display of CPM and nSv/h

- Display of Li-ion and tube voltage

- Charging facility from a USB port

- Step up converter to a stable 5.0V

- Auto-power-off after 10min

- Li-ion accu deep discharge protection

- PWM-output for an external analog meter

Unfortunately the contrast varies with the supplying

voltages. The usage of a

standard 3.7 V Li-ion rechargeable battery is a

solution to the portability and

capacity. The annoying effect of

self-discharging like regular nickel metalhydrid

accus is avoided by usage of li-ion

technology. Recharging is supplied with a

simple USB cable from any computer

interface.

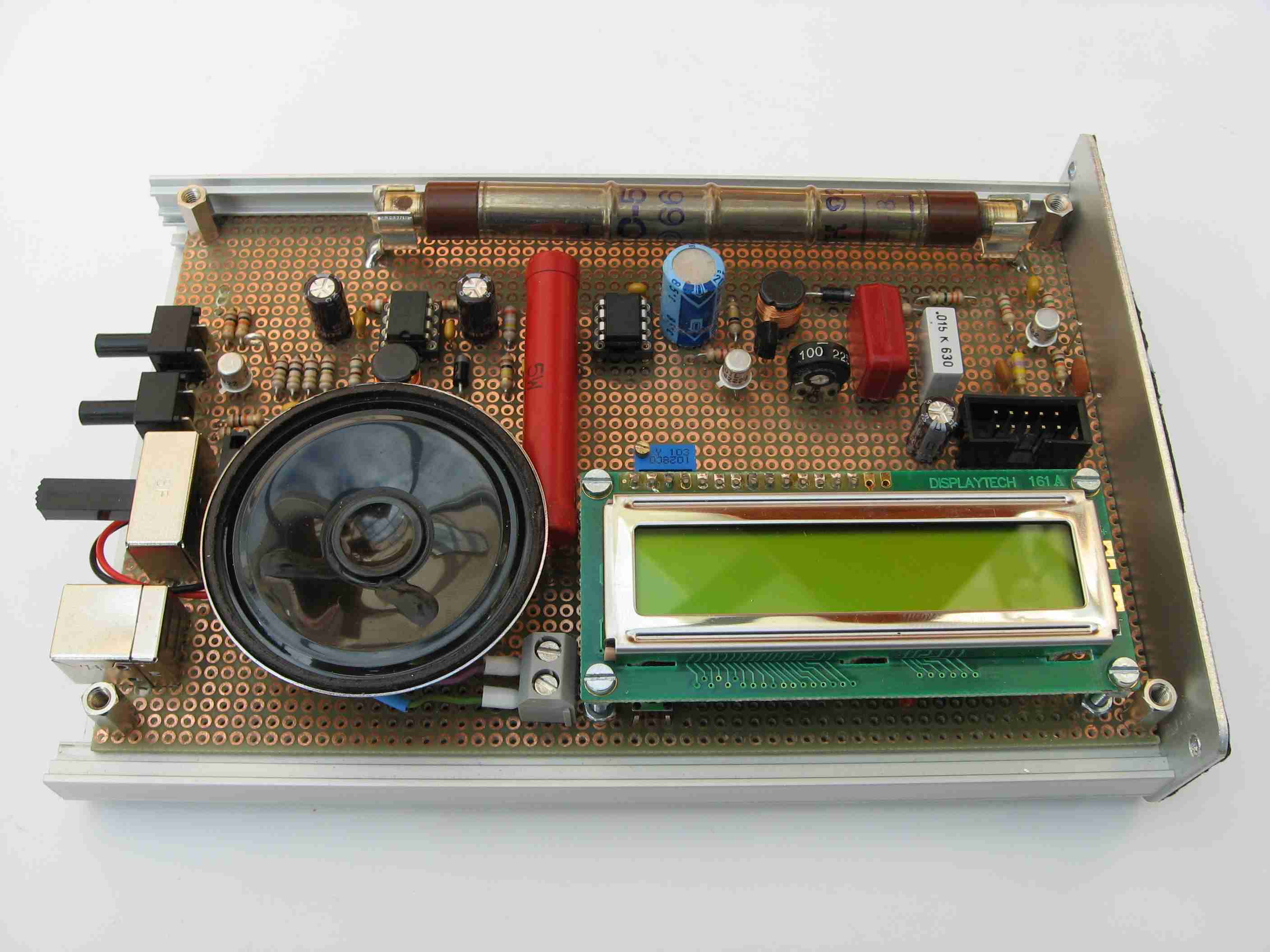

Figure 1: Geiger Counter Home Made Figure 2: PCB perf board

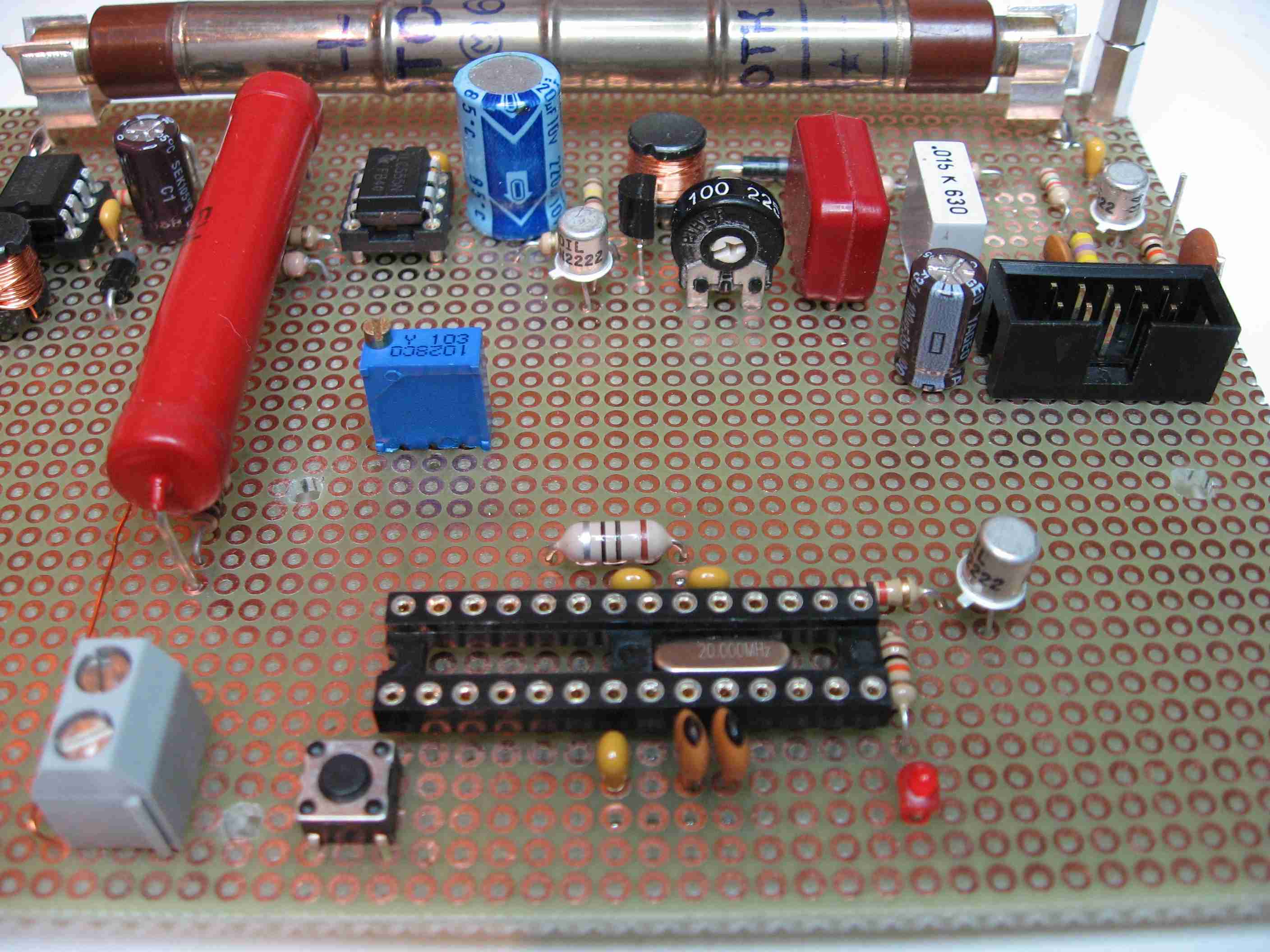

Figure 3: Socket of controller and high voltage part

The advantage of this high voltage circuit is the very low supply

current consumption and the independence of the supplying voltage.

R9 is the anode resistor for the tube. C2 and C3 are storage

capacitors for high voltage. R4 and C1 determine the on-time (30us),

C1 and R3 the off-time (3ms). During the on pulse, the current in the

coil increases with about 1mA / ms. R2 and the Ube limits the current

at 25mA and switches the Q2 off. In this moment the L1 in combination

with stray capacitance creates a 1/2 sine voltage wave about 2us long

and >400V high. This is passed by D2 to the storage capacitors C3 & C4.

This is an unwanted effect when switching a relay coil with a transistor.

This spike destroys the transistor if a freewheeling diode across the

coil is not implemented. See figure 4.

For a more detailed description see Tom Napier [1] and John Giametti [2].

Figure 4: Schematic high voltage generation

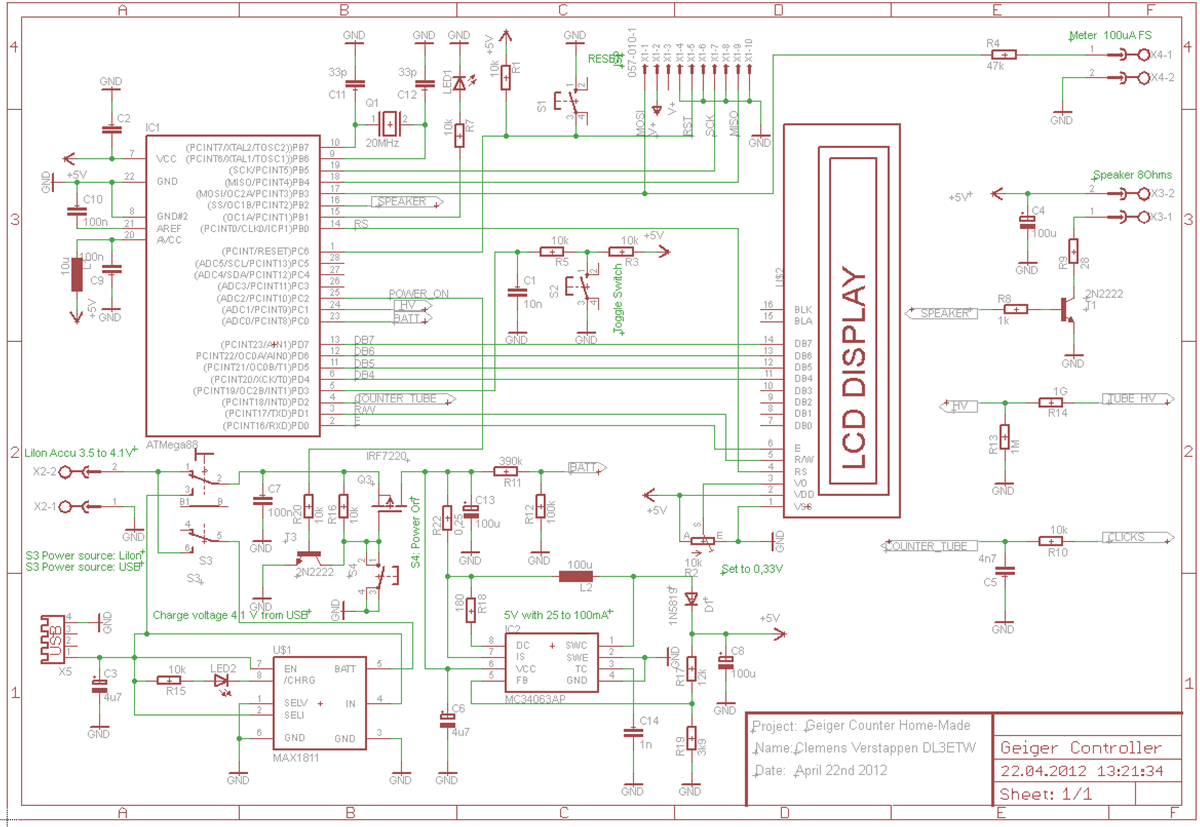

interrupt input it passes a low pass filter R10 and C5. R13 and R14 are the voltage

divider for the 400V high voltage. The ratio is 1GΩ by 1MΩ. The high values are

necessary since the high voltage is of very high impedance. Lower values would

affect the measurement accuracy. The HV signal is connected to the A/D converter

ADC1 of the controller. The battery voltage 3.7V is applied to the ADC0 with a divider

of R11 and R12. Since the internal reference voltage for the A/D converter is 1.1 volt

a reduction is necessary. A software calibration value will compensate for this.

S2 is the pushbutton for the display mode. The interrupt input INT1 is falling edge

sensitive. The RC combination debounces the switch.

The PB2 output drives the SPEAKER signal. T1 decouples and amplifies for the

8Ω speaker. The timer2 output compare (OC1A) pin is the PWM signal for the

analog meter. R4 limits the maximum current. For other than 100uA full scale meters

the value has to be adjusted. With a current of 100uA full scale the instrument is

calibrated to about 4000 CPM respective 22000nSv/h. For higher currents an

additional stage is necessary.

LED1 flashes with 0.5 Hz. A compare match of timer1 it toggles the LED and the

flag for the main program loop is set.

S3 selects the power source either from the Li-ion cell or from an USB interface.

In this case the battery charges.

X1 is the ISP (in circuit programming) connector.

CAUTION: When programming, keep power button pressed. During programming

the reset pin is kept low and the controller switches it own power off. See figure 4.

Figure 4: Schematic microcontroller

References:

[1] Napier,

Tom. Biassing G-M Tubes Isn´t So Hard, Nuts&Volts January 2004, www.nutsvolts.com

[2] DIY Geiger Counter, http://sites.google.com/site/diygeigercounter/

[4] Reichelt Elektronik GmbH & Co KG,

Tel. +49 44 22 - 9 55-3 33, http://www.reichelt.de: standard

components.

[5] Wagner, D. , DJ7BU: Selbstbau eines Geigerzählers. Funkamateur 61 (2012) H. 2, S. 154-157; http://www.funkamateur.de

[6] BERTHOLD TECHNOLOGIES

GmbH & Co. KG, Tel. +49 7081 177-0 http://www.berthold.com

[7]

Pintschka , F.: Uranglazuren http://www.frank-pintschka.de/3.html

[8] International System of Units http://en.wikipedia.org/wiki/International_System_of_Units

http://de.wikipedia.org/wiki/Internationales_Einheitensystem

[9] Conrad Electronic SE, Tel.:

0180 5 312111, http://www.conrad.de/ce/